-

Expandable Folding House

-

Quick-assembly Packing Container

-

Foldable Packing Container

-

Folding Container House

Quick-build Prefabricated Container House

The quick-build prefabricated container house is a revolutionary building type that combines the advantages of container structure, prefabricated production and rapid installation, emerging as a preferred choice for modern temporary and permanent housing needs. With its high efficiency, durability, environmental friendliness and flexibility, it has been widely applied in various fields, solving the pain points of traditional construction such as long construction period, high cost and poor adaptability.

Core Advantages: Quick Construction & High Efficiency

As the name suggests, "quick-build" is the most prominent feature of this product. Unlike traditional buildings that require on-site pouring, masonry and other cumbersome processes, the main components of the prefabricated container house are fully produced in the factory—including the container frame, wall panels, roof panels, doors and windows, and internal decoration parts. All components are pre-cut, pre-assembled and standardized, ensuring that they can be directly transported to the construction site for splicing and installation.

For a single standard container house (20ft or 40ft), the on-site installation can be completed by 2-3 workers within 1-2 days; for a combined container building with multiple units, the construction period can be shortened by 60%-80% compared with traditional buildings. This efficient construction mode greatly saves time cost, especially suitable for emergency resettlement, temporary offices, construction site dormitories and other scenarios that require rapid use.

Structural Features: Durable & Stable

The quick-build prefabricated container house adopts high-quality steel as the main frame, which inherits the excellent load-bearing capacity and impact resistance of shipping containers. The frame is treated with anti-rust, anti-corrosion and anti-oxidation processes (such as hot-dip galvanizing), ensuring that it can resist harsh weather conditions such as strong wind, heavy rain, snow and high temperature, with a service life of up to 20-30 years.

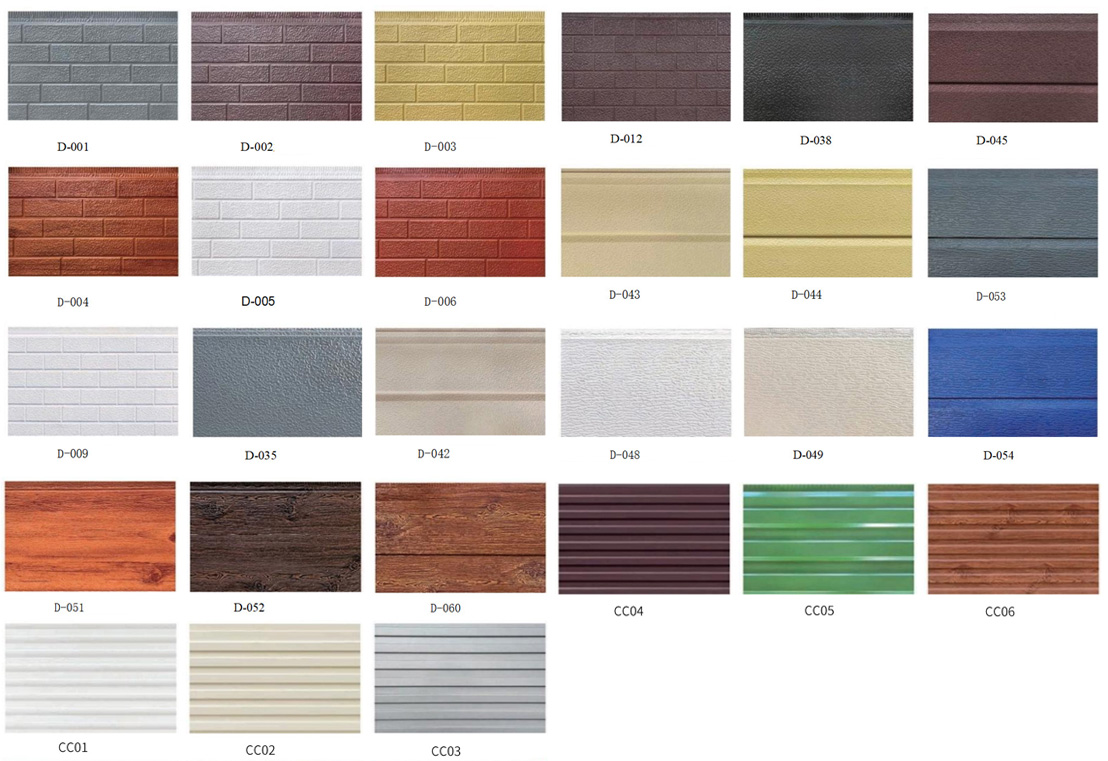

The wall and roof panels are usually made of composite materials (such as color steel sandwich panels, rock wool sandwich panels), which have both good thermal insulation, sound insulation and fire resistance performance. The tight connection between components ensures the airtightness and water tightness of the house, avoiding problems such as water leakage and heat loss. In addition, the modular design makes the structure stable and easy to maintain; if a component is damaged, it can be quickly replaced without affecting the overall use.

Flexibility & Versatility: Adapt to Multiple Scenarios

The prefabricated container house has strong flexibility in both layout and function. It can be used as a single independent space (such as a dormitory, office, storehouse) or combined into a multi-layer building through horizontal and vertical splicing, meeting the needs of large-space use (such as a conference room, classroom, hospital ward).

Its application scenarios are extremely wide: In the construction industry, it is used as temporary dormitories, offices and canteens for workers; in emergency rescue, it can be quickly deployed as resettlement houses, temporary hospitals and command centers after natural disasters such as earthquakes and floods; in daily life, it is widely used as rural villas, holiday cabins, homestays, street shops and temporary booths; in industrial and mining areas, it serves as on-site offices, dormitories and equipment rooms.