PRODUCT LIST

-

Expandable Folding House

-

Quick-assembly Packing Container

-

Foldable Packing Container

-

Folding Container House

Flat-pack Container Cabin

Extended dimensions:6055*W2990*H2896mm

15 sets in a 40 foot high container

TAG:

Prefab Flat-pack Container Unit Quick-build Prefabricated Container House Fast-assembly Flat-pack Container House

E-mail:

19303280380@163.com

The Flat-pack Container Cabin is an innovative, cost-effective and highly portable prefabricated building solution, designed to address the growing demand for flexible, efficient and sustainable construction across various scenarios. Unlike traditional assembled container houses, its core advantage lies in the flat-pack design—all structural components are disassembled, folded and bundled for transportation, maximizing logistics efficiency while minimizing shipping costs and storage space. Crafted with high-quality materials and standardized factory production, this cabin combines rapid assembly, durability and customization, making it an ideal choice for both temporary and semi-permanent use.

At the heart of the flat-pack container cabin is its optimized flat-pack structure, which revolutionizes transportation and on-site construction. All key components—including cold-formed steel frames, insulated wall panels, floor slabs and roof structures—are precision-manufactured, pre-welded (where necessary) and strictly tested in the factory before being bundled into compact packages. A notable highlight is its exceptional transportation efficiency: up to 4-8 flat-pack units can be nested or bundled into a single standard 40-foot shipping container, reducing transportation costs by up to 75% compared to fully assembled container cabins. This compact packaging also makes it easy to transport to remote or hard-to-reach locations, such as mountainous construction sites, rural areas or off-grid regions, where traditional building materials are difficult to deliver.

Rapid and hassle-free assembly is another defining feature of this cabin. Designed for simplicity, the prefabricated components feature precise positioning and standardized connection points, eliminating the need for complex on-site welding or heavy construction machinery. With basic tools and a small team of 2-4 workers, a single standard flat-pack container cabin can be fully assembled and ready for use within 2-6 hours; even multi-unit combinations or small multi-storey structures can be completed in just a few days. The assembly process follows a straightforward sequence: leveling the simple foundation (optional concrete strip foundation or steel support), installing corner posts and floor frames, attaching wall panels, fixing the roof structure, and finally fitting doors, windows and internal fittings—no professional construction experience is required, greatly reducing labor costs and construction cycles.

In terms of structural performance and comfort, the flat-pack container cabin excels with its robust design and humanized configuration. The main frame is made of high-strength corten steel or galvanized steel, ensuring excellent durability, corrosion resistance, wind resistance (Grade 10-12) and earthquake resistance (Grade 6-7), capable of withstanding extreme weather conditions such as heavy rain, strong winds and high temperatures. The wall, floor and roof adopt integrated insulated sandwich panels, filled with non-combustible mineral wool or polyurethane core material, which effectively achieves thermal insulation, sound insulation and fire resistance effects—keeping the internal space warm in winter and cool in summer, while blocking external noise and reducing energy consumption for heating and cooling. The cabin is also equipped with standardized reserved holes for water, electricity, lighting and air conditioning, allowing direct connection to supporting facilities for immediate use after assembly.

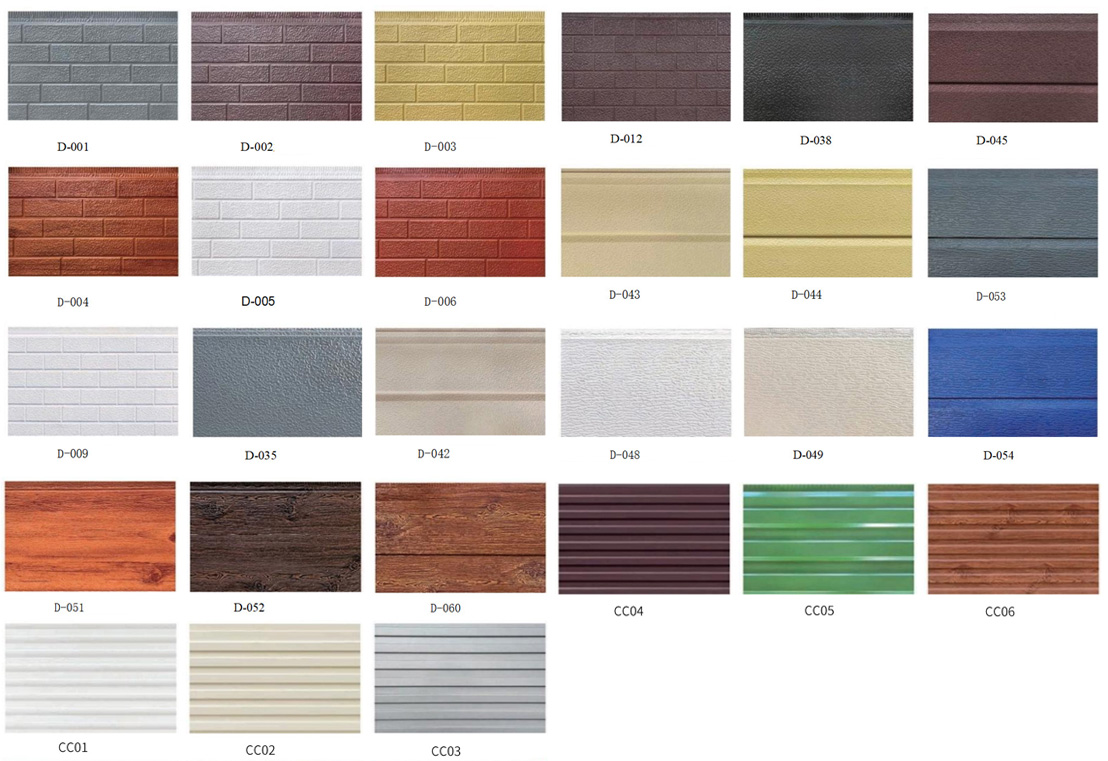

Flexibility and customization are key strengths that make the flat-pack container cabin adaptable to diverse needs. Available in standard sizes (10ft, 20ft, 40ft) or custom dimensions, it can be used as a single-unit space (such as a worker dormitory, on-site office, storage room or temporary medical station) or combined horizontally and stacked vertically to form multi-room, multi-storey structures (such as employee dormitory buildings, comprehensive on-site service centers or pop-up commercial spaces). The internal layout can be fully customized according to user requirements: partitions can be added to create separate rooms, and additional configurations such as toilets, washing areas, desks, beds or storage cabinets can be installed. Externally, it can be customized with anti-corrosion coatings (for coastal or humid areas), different colors of exterior panels, rainproof awnings or guardrails to match the surrounding environment and use needs.

Eco-friendliness and cost-effectiveness further enhance the competitiveness of this product. Made of recyclable and reusable steel materials, the flat-pack container cabin generates no construction waste during installation, aligning with the global green and low-carbon construction concept. Its detachable and reusable design allows components to be disassembled, transported and reassembled multiple times when the project is transferred or use needs change, greatly reducing the overall use cost and resource waste. Additionally, the standardized factory production reduces material waste and production costs, while the rapid on-site assembly shortens the construction period and lowers labor expenses—offering high cost performance for large-batch use such as construction site accommodation or emergency resettlement.

With its wide application scope, the flat-pack container cabin is widely used in engineering construction (worker dormitories, on-site offices), municipal emergency (disaster relief shelters, temporary command posts), tourism and camping (mobile camps, vacation cabins), rural revitalization (temporary service stations, rural homestays), commercial services (pop-up stores, temporary exhibition halls) and other fields. It perfectly balances portability, durability, comfort and customization, breaking the limitations of traditional construction and providing a flexible, efficient and reliable building solution for modern construction needs.